Hot melt adhesive films have emerged as a preferred material for bonding, outpacing traditional liquid adhesives in washability and temperature endurance. However, challenges remain, including instances where the adhesive film does not fully melt. Drawing from extensive industry experience, we examine the reasons behind this phenomenon and offer insights into ensuring optimal adhesive performance.

Data Analysis:

Statistics from the Adhesive and Sealant Council reveal that hot melt adhesive films are utilized in over 60% of material compounding processes, highlighting their dominance in the market. Yet, a significant 15% of (bonding) issues are attributed to incomplete melting of the adhesive film.

Common Challenges and Solutions:

-

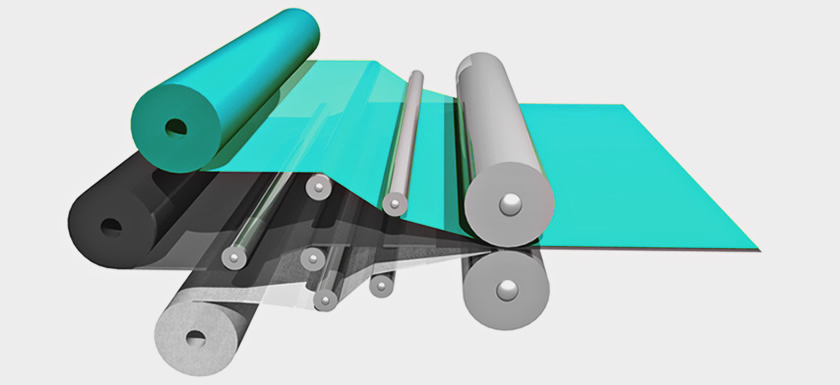

Inadequate Melting Conditions: Insufficient temperature, time, or pressure can impede the melting process. Each type of hot melt adhesive film has a specific melting point, and failure to meet these requirements can compromise the adhesive's effectiveness. Adjusting the melting conditions can often resolve such issues.

-

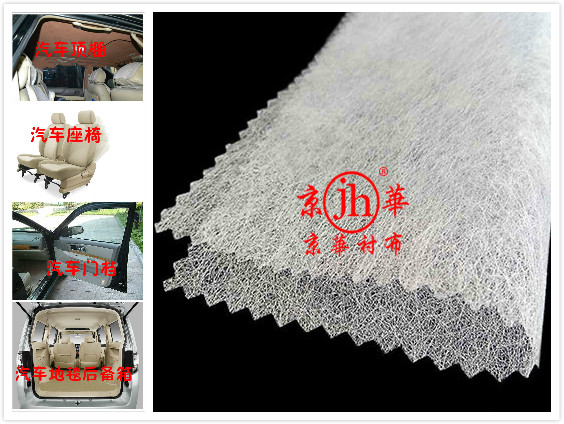

Quality of the Adhesive Film: The integrity of the hot melt adhesive film itself is paramount. Defective films can lead to incomplete melting, affecting the bond's quality. It is advisable to source hot melt adhesive films from reputable manufacturers to ensure product quality and performance.

Case Study:

A leading manufacturer of automotive components reported a 30% reduction in bonding failures after switching to a high-quality hot melt adhesive film from a certified producer. The change was accompanied by a systematic review of their melting protocols, resulting in a more reliable and efficient bonding process.

Conclusion:

The selection and application of hot melt adhesive films are critical for achieving robust material bonds. By understanding the factors that contribute to incomplete melting and choosing high-quality products, industries can enhance the effectiveness of their compounding processes.

Closing Remarks:

As the market leader in adhesive films, hot melt adhesive films continue to set the standard for performance and sustainability. With careful consideration of melting conditions and a commitment to quality, these adhesives can significantly improve product integrity and streamline manufacturing processes.