Embroidered trademarks can be said to be an important accessory in the clothing industry, often consisting of iconic patterns affixed to clothing for decorative purposes. The traditional process involves stitching embroidered logos onto clothing fabrics using needle and thread. This process is not only inefficient, but sometimes the embroidered logo falls off due to reasons such as thread detachment, affecting the overall quality of the clothing and making it difficult to elevate its grade. After adopting the hot melt adhesive mesh bonding process, the bonding of embroidered trademarks is more efficien

3.Production of outdoor clothing

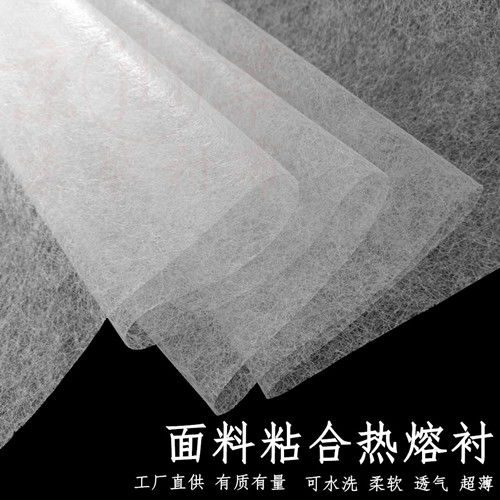

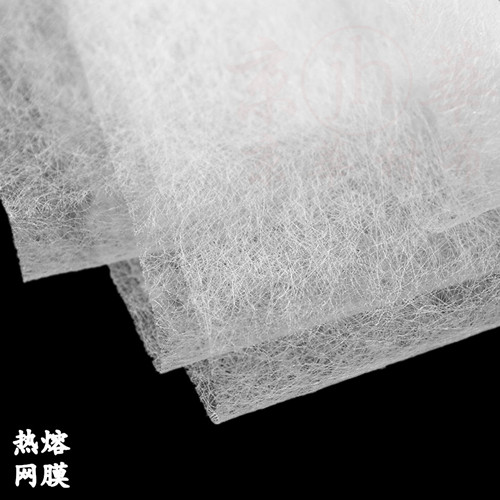

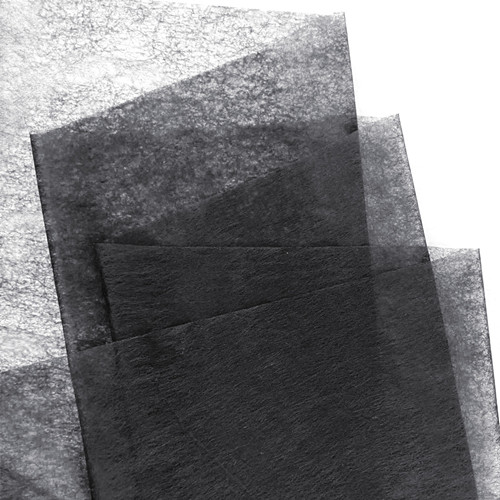

In the production of multifunctional clothing, hot melt adhesive mesh has a wide range of applications, such as the lamination of waterproof fabrics in assault suits. If sewing technology is used, the needle hole is often the main channel for water leakage, which affects the overall user experience of the clothing. At this point, it is necessary to use hot melt adhesive film to fit and splice waterproof fabrics, improving the overall waterproof performance of the clothing. In addition, items such as waterproof zippers and pockets involve the use of hot melt adhesive films.

4.Production of functional clothing

Functional clothing refers to clothing with certain functions in certain special industries. Like reflective clothing, it is necessary to stick a cloth bag containing fluorescent substances on the clothing to make it reflective.

The traditional method also uses seam sewing technology, which is inefficient and cannot be waterproof. The use of hot melt adhesive mesh film in the back glue pressing process not only greatly improves production efficiency, but also makes the clothing have good waterproof function and increases the overall aesthetics of the clothing, making it more practical.

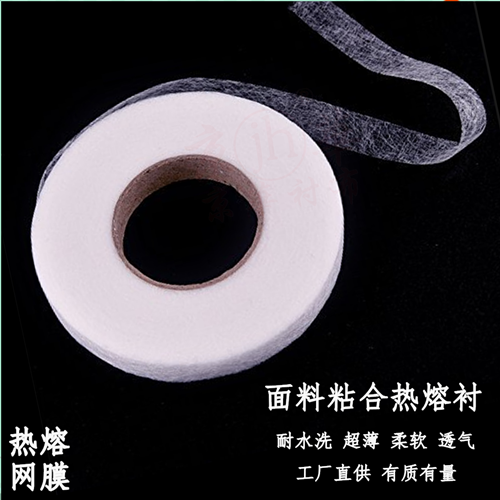

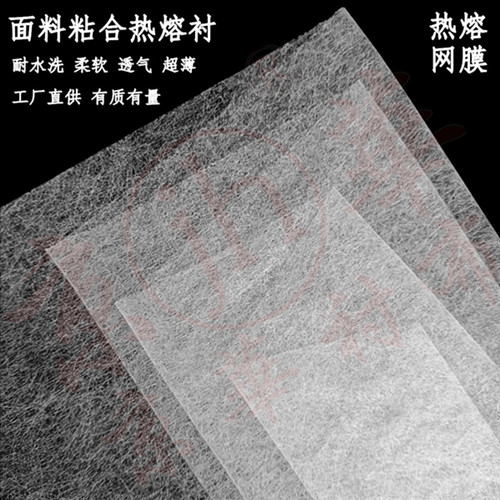

5.The fitting of clothing lining

The use of hot melt adhesive mesh instead of clothing lining has gradually become a niche process choice in the collar and cuffs of clothing. The demand for softness varies for different fabrics, and hot melt adhesive mesh can provide fabrics that meet different needs. Silk fabrics generally require a high degree of softness, while some special occasions require a crisp feeling.

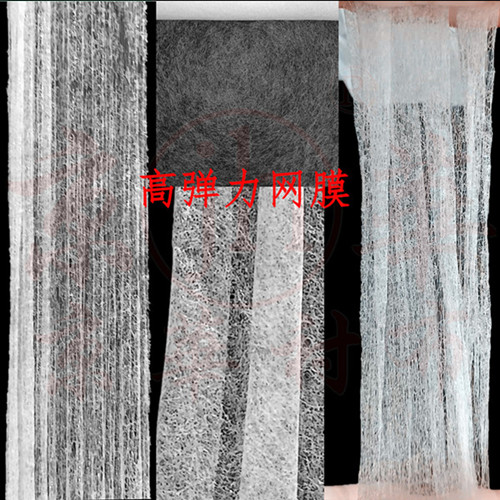

6.Production of seamless ship socks

Traceless boat socks are an essential tool for women to release their beautiful feet in the summer, and are highly favored by female consumers. The use of hot melt adhesive mesh film is also indispensable. In the production of ship socks, as socks are frequently washed and pulled clothes, hot melt adhesive mesh film with good elasticity is often used, which should have good rebound performance and good water resistance. Such socks can only be more durable after production.